Improving production and packaging efficiency through automation

The automation of packaging processes brings many benefits to businesses, including a reduction in the risk of errors and damage to goods, which directly translates into improved product quality. By eliminating human errors, such as damage to goods or incorrect packaging, modern packaging machines play a key role in this process. Below, we discuss in more detail how packaging machinery affects these aspects.

Ways to increase production efficiency

Production efficiency is one of the most important performance indicators of a company. It signifies how efficiently a company uses its resources to produce products. By automating production and packaging, this process can be optimised by reducing the time needed for production, minimising errors and increasing flexibility to adapt to changing market requirements.

Precision in packaging machines

Packaging machines are programmed to operate with the utmost precision, eliminating the risk of errors caused by human factors such as fatigue or inattention. As a result, the packaging process is more consistent and less prone to error, increasing the overall quality of the final product.

In addition, modern packaging machines are equipped with sophisticated quality control systems to detect irregularities in the packaging or product. In this way, defective batches of products can be quickly identified and eliminated.

Protection against damage

Automated packaging also provides protection against damage to goods. The machines adapt the pressure and material handling to the type of product, which is particularly important when packing fragile and easily damaged items.

With increased precision and quality control, packaging machines contribute to a reduction in customer complaints, which directly affects customer satisfaction and brand loyalty.

Improving the quality and aesthetics of packaging

With a highly competitive market, there are increasing demands on the quality and appearance of goods. Automated packaging systems make it possible to achieve consistency and identical packaging appearance, which improves brand image and increases competitiveness. Packaging aesthetics are of great importance to customers, who often judge a product at the first impression stage.

Safety and ecology

Packaging automation must meet stringent safety standards and comply with current regulations. This is particularly important in industries where compliance with hygiene and safety standards is crucial. It is also important to ensure that employees are adequately trained to use the new machines.

In an era of increasing environmental awareness, companies are increasingly paying attention to the environmental impact of their operations. Packaging automation can contribute to reducing waste and increasing the efficiency of packaging materials.

Summary

Investment in modern packaging systems bring a range of benefits to businesses, including increased productivity, reduced costs, reduced risk of errors and improved packaging aesthetics. Companies that opt for such solutions gain a competitive advantage and enjoy greater customer satisfaction, which is crucial in today's dynamic business environment.

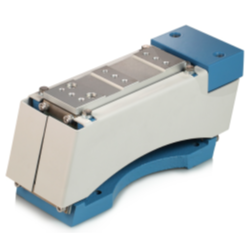

NTL 650B linear vibrator base

NTL 650B linear vibrator base  SDVC34-UR controller with automatic adjustment

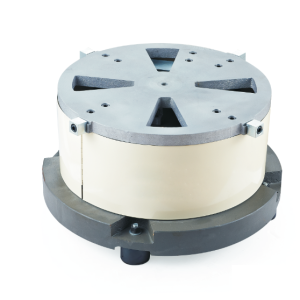

SDVC34-UR controller with automatic adjustment  Vibration base NTB-46

Vibration base NTB-46  Right-hand bowl S-300-35

Right-hand bowl S-300-35