More and more people are discovering the benefits of vacuum packaging as an effective method of prolonging food freshness. This state-of-the-art technique, previously reserved mainly for the food industry, is becoming increasingly available in domestic kitchens, offering remarkable opportunities to save money and reduce food waste. By eliminating oxygen from packaging, food products can retain their freshness up to several times longer than with traditional storage methods.

Principles of vacuum technology

Vacuum packing is the technological process of removing air from an airtight container before it is sealed. The removal of oxygen is a key part of this method, as it is the presence of this gas that most accelerates putrefaction processes and the growth of micro-organisms. Without access to air, aerobic bacteria cannot grow, which dramatically slows down the spoilage of food products. In addition, the lack of oxygen prevents the auto-oxidation of fats, the oxidation of vitamins and enzymatic browning reactions that negatively affect food quality.

The process is carried out using specialised equipment - vacuum packers - which first extract the air from special containers or bags and then hermetically seal them. For this purpose, the following are used plastic bags for food packaging, which are characterised by resistance to high temperatures and a special structure to ensure sealing over a long period of time. These dedicated packaging materials are very different from ordinary grocery bags, offering much better barrier properties and resistance to external factors.

Specific storage periods for different product categories

The shelf life of vacuum-packed food varies considerably depending on the type of product and storage conditions. Meats are the category that benefits most from this technology - large cuts of beef, pork or mutton can be stored in the freezer for up to 2-3 years, while smaller portions remain fresh for around a year. Fresh fish lasts up to 12 months in freezer conditions, a significant improvement over traditional storage.

Dairy products with their extended shelf life are impressive - vacuum-packed cheddar cheese can stay fresh in the fridge for 6-9 months and in the freezer for up to 1-2 years. Prepared meals, soups and processed meats gain an approx. 4-fold increase in shelf life. Vegetables and fruit, when properly prepared, can remain fresh 3-5 times longer than with conventional storage methods.

| Product | Traditional storage | Vacuum storage | Storage conditions |

|---|---|---|---|

| Raw beef | 3-4 days (fridge) | 30-40 days (fridge) | Refrigerator (+5°C) |

| 6 months (freezer) | 24-36 months | Freezer (-18°C) | |

| Poultry (chicken) | 1-2 days (fridge) | 6-9 days (fridge) | Refrigerator (+5°C) |

| 6 months (freezer) | 24 months | Freezer (-18°C) | |

| Fresh fish | 1-3 days (fridge) | 4-7 days (fridge) | Refrigerator (+5°C) |

| 6-12 months (freezer) | 24-36 months | Freezer (-18°C) | |

| Hard cheeses (cheddar) | 15-20 days (fridge) | 40-60 days (fridge) | Refrigerator (+5°C) |

| Raw vegetables | 3-5 days (fridge) | 10-20 days (fridge) | Refrigerator (+5°C) |

| Bakery products | 1-2 days (room temperature) | 7-8 days (room temperature) | Room temperature |

| Prepared dishes | 2-3 days (refrigerated) | 8-12 days (fridge) | Refrigerator (+5°C) |

Notes:

- Key terms: Extensions require airtight packaging and immediate cooling after packaging.

- Blanching of vegetables before packaging extends shelf life by an additional 30%.

- For frozen meats it is recommended double packing in plastic bags for food packaging to minimise the risk of damage.

Factors determining the effectiveness of vacuum packaging

The efficiency of the vacuum packaging process depends on several key factors that directly influence the end result. The initial quality of the product is fundamental - only fresh, intact ingredients can fully benefit from the advantages of this technology. Packaging products that have already started the spoilage process will not only fail to deliver the expected results, but may also pose a health risk.

The level of vacuum achieved and the quality of the seal have a direct impact on storage life. Even a small leak can lead to air infiltration, which significantly reduces the freshness of the product. Storage temperature is another important consideration - vacuum-packed products require a constant fridge temperature (around 4°C) or freezer temperature (-18°C) for maximum benefit.

Comparison with traditional storage methods

The juxtaposition of vacuum packaging and conventional methods reveals spectacular differences in the shelf life of products. A poultry breast stored under normal fridge conditions will remain fresh for only 2-3 days, while it will last up to 9 days when vacuum-packed. Meat stored in the freezer by conventional methods stays fresh for about 6 months, while vacuum-packed can be stored for up to 4 years.

Hard cheeses, which normally last 1-2 weeks in the fridge, retain their quality for 4-8 months when vacuum-packed. Similar proportions apply to fruit - while fresh fruit in the fridge remains edible for 1-6 days, vacuum-packed fruit can remain fresh for 1-2 weeks. These dramatic differences are due to the elimination of the main factors that cause food spoilage.

Practical tips for maximum efficiency

To achieve optimum results, a few basic rules must be followed. Products should be thoroughly cleaned and dried before packaging, and hot foods must be cooled to room temperature. Vegetables often need to be blanched before vacuum packaging, which further extends their shelf life. It is also important to leave enough space in the bag to allow for proper sealing.

Labelling packaged products with the date of packaging and contents makes it easier to monitor use-by dates. Even the most advanced vacuum packaging does not stop ageing processes completely - products still need to be monitored for signs of spoilage, such as a change in colour, smell or texture.

Safety and limitations of the method

Despite its many advantages, vacuum packaging is not a universal solution to all food storage problems. The elimination of oxygen does not guarantee complete sterilisation of products, and some anaerobic bacteria can still thrive under vacuum. Particular care should be taken with products containing garlic or oil, which can encourage the growth of dangerous micro-organisms under anaerobic conditions.

Vacuum-packed products require constant refrigeration or freezing - room temperature significantly shortens the safe storage period. Once the packaging has been opened, the food should be consumed within a few days, as renewed contact with oxygen accelerates spoilage processes.

Vacuum packaging represents a breakthrough technology in the field of food storage, offering the possibility to extend the freshness of products by up to several years. The key to success is the correct application of this method, taking into account the specific characteristics of individual products and maintaining the right storage conditions. In this way, you can significantly reduce food waste, save money and enjoy fresh products for a much longer period of time.

FAQ - Frequently asked questions

Can all types of food be vacuum packed?

Most food products are suitable for vacuum packing, but some require special care. Products with garlic, mushrooms or soft fruit may require special preparation. Avoid packing products with sharp edges that may damage the films.

How do you know if vacuum-packed food has spoiled?

Signs of spoilage of vacuum-packed products include: the appearance of mould, dark stains, an unpleasant odour, a change in consistency to slippery or dried and discolouration. If in doubt, the product should be discarded.

Does vacuum packing require specialised equipment?

Yes, for effective vacuum packing you need a vacuum packer and dedicated bags or containers. There are both professional machines and cheaper home versions available. Alternatively, you can use a pump or zipper bag method, although the efficiency will be lower.

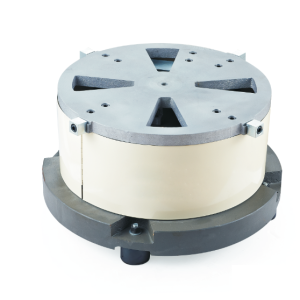

Vibration base NTB-46

Vibration base NTB-46  Right-hand bowl S-300-35

Right-hand bowl S-300-35