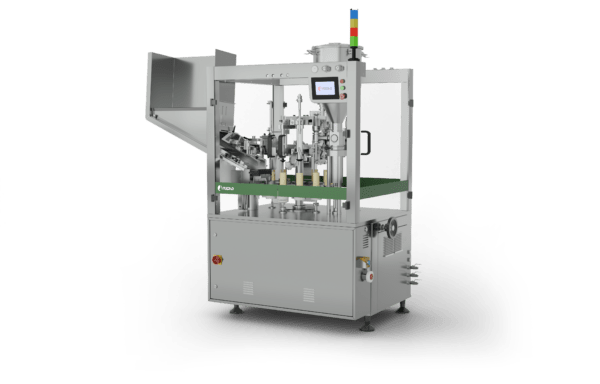

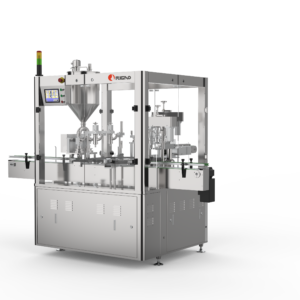

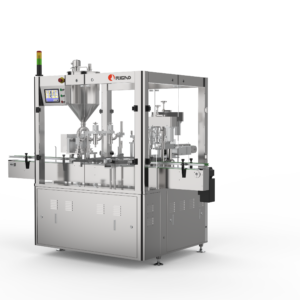

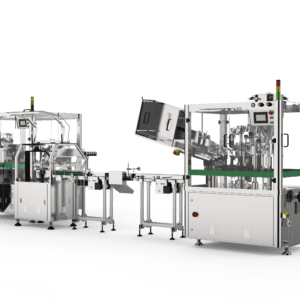

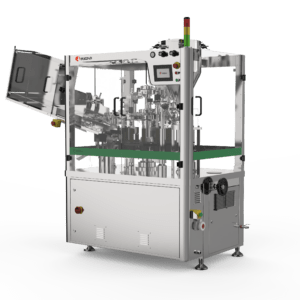

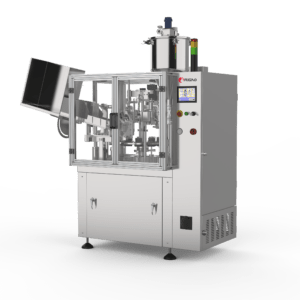

Tuber RGNF-60A

The RGNF-60A tube machine is an advanced automatic machine designed for filling and sealing plastic or aluminium tubes. The machine is designed to meet the requirements of the cosmetic, pharmaceutical and food industries, offering precise dispensing and reliable packaging of creams, gels, pastes and other products with a thick consistency. Thanks to its compact design and intuitive interface, the tube maker ensures high production efficiency while maintaining the highest packaging quality standards

- Product available on request

Tube maker and tube sealing machine - Technology and functionality in one

The RGNF-60A tube maker uses advanced technology to ensure the precision and repeatability of the packaging process. At the heart of the machine is an automated tube feeding system from a magazine, which is replenished manually by the operator. The machine automatically picks up the tubes and places them in the slots, where they are stabilised before the next packaging steps..

The packaging process begins with the accurate positioning of the tube using a contrast sensor that recognises the marker on the packaging. This ensures that each tube is oriented in an identical way, ensuring an aesthetically pleasing and uniform appearance of the final products. Once properly positioned, the tube goes under the pouring section, where the product is precisely dispensed using high-end servo drives.

The size of the dosage is set automatically on the intuitive TOUCH PANEL control panel, allowing precise control of the amount of product to be filled. In the next step, the sealing area is heated using hot air, the tube is then sealed and the excess material is cut off. The finished product is then automatically ejected from the tube maker cavity outside the machine area.

An essential component of the system is the product level sensor in the tank, which controls the amount of available medium and prevents a shortage during the production process. Thanks to the use of servo drives, the entire process runs smoothly, quickly and with maximum efficiency.

Key features

-

-

High performance - the RGNF-60A allows for a significant increase in packaging speed compared to manual methods, resulting in increased productivity

-

Precise metering - an advanced dispensing system ensures repeatability and accuracy in filling each tube

-

Automatic tube orientation - a contrast sensor is responsible for the perfect positioning of each pack

-

Quick exchange of formats - the design of the machine allows immediate changeover to a different packaging format, increasing production flexibility

-

Intuitive control panel - easy-to-use touchscreen interface allows quick programming of operating parameters

-

Water cooling system - efficient heat dissipation ensures stable operation even during long-term production

-

Advanced quality control - in-built monitoring systems of process parameters guarantee consistency and high quality of packaging

-

Expandable - the modular design allows the functionality of the machine to be extended with additional components such as daters or marking systems

-

Benefits for your company

Investing in the RGNF-60A tube maker brings a number of tangible benefits to the company. First and foremost, automating the packaging process significantly reduces operating costs by minimising employee involvement and eliminating human error, resulting in fewer defective products.

The implementation of a modern tube maker also increases production flexibility, as the machine can be quickly converted to a different packaging format, allowing a variety of products to be handled on one machine. Changeover time is only a few minutes, which minimises production downtime and increases the overall efficiency of the packaging line.

Increased occupational safety is also a significant advantage, as the automation of packaging processes eliminates the risk of injury associated with monotonous, repetitive manual work. In addition, the RGNF-60A tube maker helps to save on packaging materials through precise dispensing and sealing, which reduces production waste.

Improving the quality of the final product is also a significant advantage. Each tube is filled with identical accuracy, sealed in the same way and has a uniform appearance, which enhances the aesthetics of the products and increases customer satisfaction. Higher quality packaging results in longer product shelf life and better protection of the contents.

Examples of solutions:

The RGNF-60A tube maker can be equipped with a range of additional modules and functions to adapt the machine to specific production requirements:

Cosmetics industry

-

Filling tubes with face and body creams

-

Dosage of masks, scrubs and other skin care products

-

Packaging of conditioners and hair masks

Pharmaceutical industry

-

Production of medicinal ointments and creams

-

Packaging of analgesic and anti-inflammatory gels

-

Dosage of dermatological preparations

Food industry

-

Filling tubes with flavour pastes and concentrates

-

Packaging of sauces and culinary additives

-

Dosing of high-viscosity products

Household chemicals industry

-

Production of cleaning pastes

-

Packaging of adhesives, silicones and other technical products

-

Dosage of toothpaste

Why choose Tarpak tubing machines?

When you choose tube machine solutions from Polish packaging machine manufacturer Tarpak, you gain:

-

Local service and technical support - rapid response and support throughout the country

-

Industry experience - long-standing presence on the market and specialisation in packaging machines

-

Competitive prices - value for money

-

Customisable solutions - adaptation of machines to specific customer needs

-

A qualified team - professional advice and service at every stage of cooperation

-

Innovative solutions - state-of-the-art technology to ensure reliability and precision

Tarpak is a company with tradition, operating in the market since 2005, which has established itself as a distinguished manufacturer of packaging machines. By choosing tubular machines from this brand, you not only get a high-quality machine, but also comprehensive support at every stage of cooperation.

The company provides a full service - from the delivery of the machine, to the installation and training of personnel, to the provision of an efficient service. With a skilled and experienced team, Tarpak also offers customisation of machine configurations to suit each customer's individual needs.

Tarpak tubing machines stand out in the market for their reliability and precise operation, which translates into a long service life of the machines and high quality of packaged products. The company relies on innovative solutions so that its machines are always in line with the latest trends in packaging process automation.

Right-hand bowl S-300-35

Right-hand bowl S-300-35