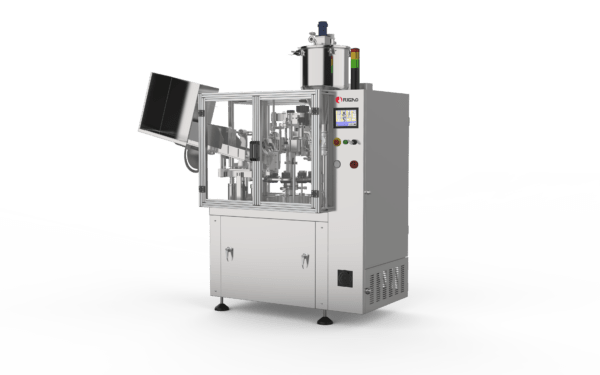

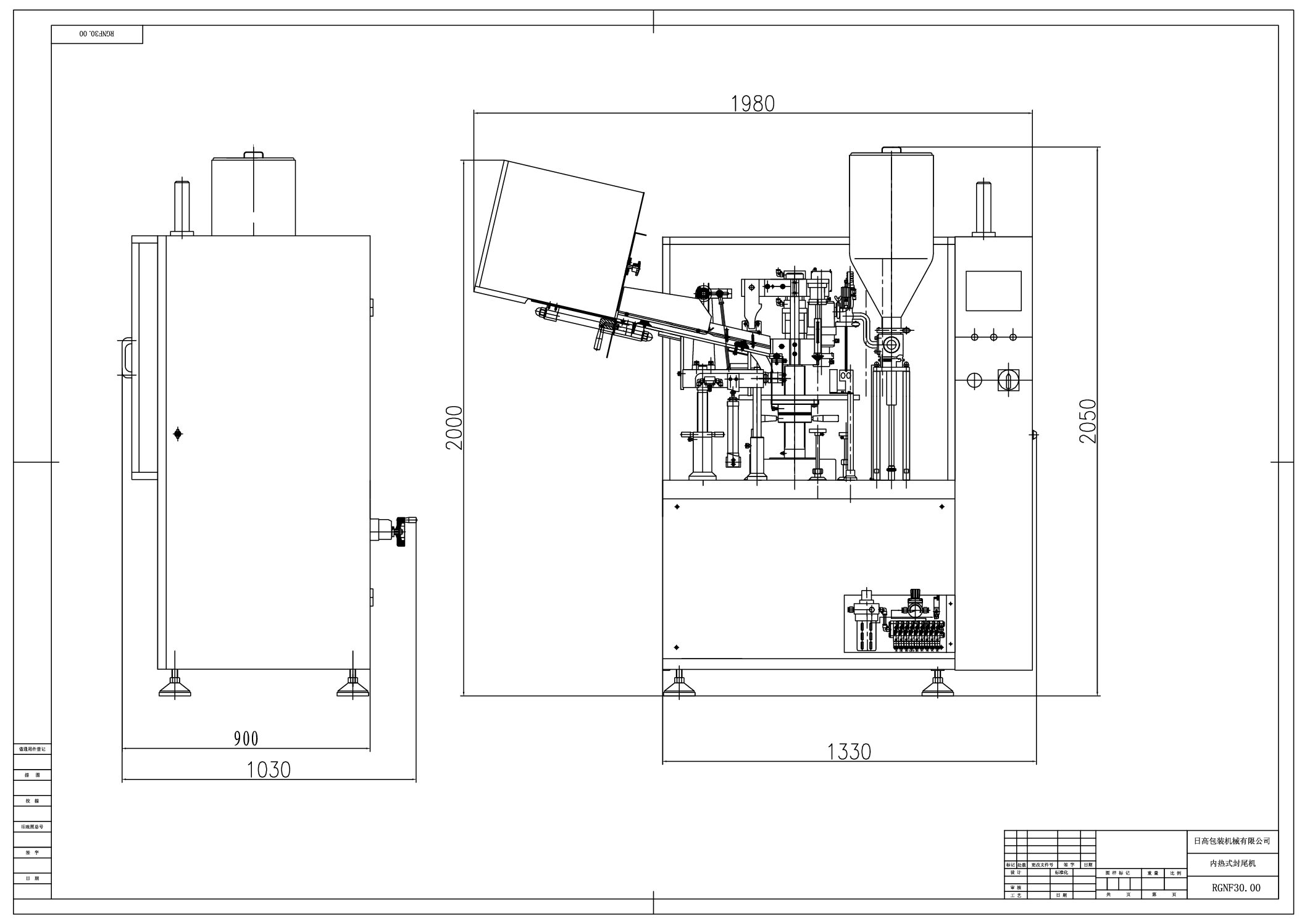

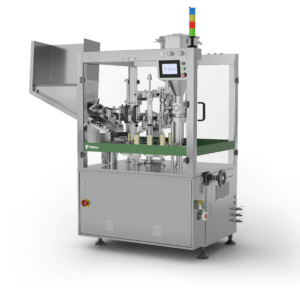

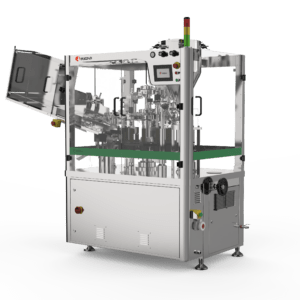

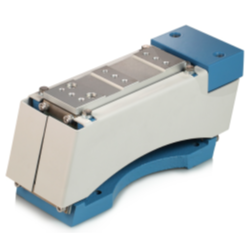

Tuber RGNF-30B

The RGNF-30B tube machine is an advanced semi-automatic machine designed for filling and closing plastic and laminated tubes. The machine is characterised by high productivity (1800-2400 tubes/hour), filling precision (≤±1%) and versatility of applications in the pharmaceutical, cosmetic, food and household chemical industries. The RGNF-30B combines state-of-the-art technology with intuitive operation to provide an efficient packaging process for products ranging from semi-liquid to thick consistency.

- Product available on request

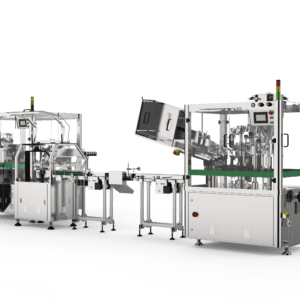

Tube and tube sealing machine - Innovative packaging machine solution

The RGNF-30B tube machine is a specialised machine designed for efficient filling and sealing of plastic and laminated tubes in a variety of industries. The machine uses advanced pneumatic tube feeding technology via a vacuum system, ensuring the precision and reliability of the entire process.1. Thanks to the state-of-the-art touchscreen PLC control, operation of the machine is extremely simple and intuitive.

The RGNF-30B automatically completes the full production cycle - from feeding empty tubes, identifying and filling them, to hot air sealing, trimming, code printing and ejection of the finished product. The machine creates PET tubes, which are characterised by high mechanical strength and dimensional stability.. Depending on the type of product to be dosed, a suitable dosing nozzle can be selected..

The unit is designed to high hygiene standards - all surfaces in contact with the product have a smooth finish or are made of corrosion-resistant stainless steel. The design of the machine effectively excludes the possibility of substances penetrating into the product.

Key features

-

High production capacity - 1800-2400 tubes per hour (adjustable)

-

Precise control of filling - accuracy of ≤±1%

-

Versatility - supports tubes with a diameter of 10 to 50 mm and a length of up to 210 mm

-

Capacious tank - with a volume of 40 litres

-

PLC control system with touch screen - provides easy and intuitive operation

-

Pneumatic tube feeding - by means of a vacuum device

-

Intelligent temperature control system - for optimum weld quality

-

Built-in photocell - allows working with plain and printed tubes

-

Compact dimensions - 1900(L)×850(W)×1900(H)mm with a weight of approx. 850 kg

-

High-quality components - European components (Weintec, Siemens, Panasonic)

Benefits for your company

The implementation of the RGNF-30B tube maker into the production process brings numerous operational and economic benefits:

-

Automation of the packaging process - significantly increases production efficiency, resulting in time and cost savings

-

Dosing precision - minimises product loss and ensures dosing repeatability of ≤±1%

-

Versatility of applications - possibility to work with different types of products and tubes of different sizes

-

High quality final packaging - aesthetically pleasing and tightly sealed tubes contribute to the positive perception of the product by customers

-

Ease of operation and maintenance - intuitive control panel and simple design reduce staff training and servicing costs

-

Optimisation of production space - the compact size of the unit allows efficient use of factory space

-

High hygiene standard - design that excludes the risk of product contamination

Examples of solutions:

The RGNF-30B tube machine is used in many industries:

Cosmetics industry

-

Filling tubes with face and body creams

-

Dosage of masks, scrubs and other skin care products

-

Packaging of conditioners and hair masks

Pharmaceutical industry

-

Production of medicinal ointments and creams

-

Packaging of analgesic and anti-inflammatory gels

-

Dosage of dermatological preparations

Food industry

-

Filling tubes with flavour pastes and concentrates

-

Packaging of sauces and culinary additives

-

Dosing of high-viscosity products

Household chemicals industry

-

Production of cleaning pastes

-

Packaging of adhesives, silicones and other technical products

-

Dosage of toothpaste

Why choose Tarpak tubing machines?

When you choose tube machine solutions from Polish packaging machine manufacturer Tarpak, you gain:

-

Local service and technical support - rapid response and support throughout the country

-

Industry experience - long-standing presence on the market and specialisation in packaging machines

-

Competitive prices - value for money

-

Customisable solutions - adaptation of machines to specific customer needs

-

A qualified team - professional advice and service at every stage of cooperation

-

Innovative solutions - state-of-the-art technology to ensure reliability and precision

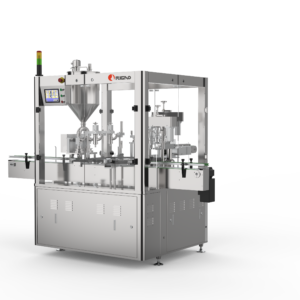

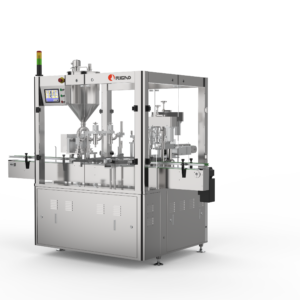

NTL 650B linear vibrator base

NTL 650B linear vibrator base