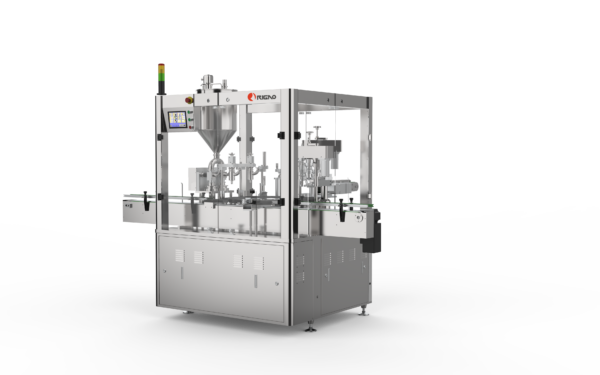

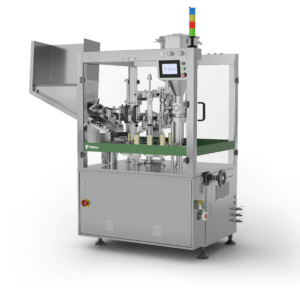

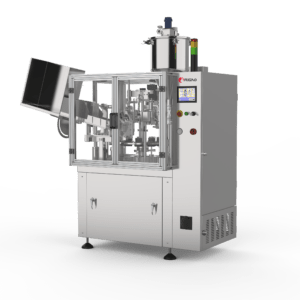

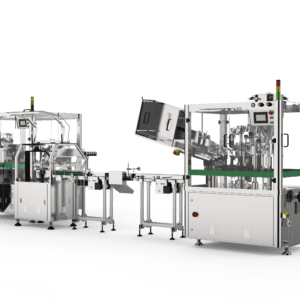

Tubing machine RGA-GX45A

The advanced industrial tube machine provides a versatile solution for the pharmaceutical, food, cosmetic and chemical industries. The unit provides precise filling of liquids and pastes, automatic plugging and capping with an accuracy of ±1%. The modular system allows quick adaptation to different production needs, while a capacity of 35-40 pieces per minute guarantees efficiency in an industrial environment. The machine has been designed according to GMP requirements, using the highest quality materials, including 316L stainless steel, thus ensuring hygienic production conditions.

- Product available on request

The industrial tube maker is an advanced machine designed to provide a comprehensive process for filling, plugging and capping bottles in a variety of industries. The machine has been designed for use in the pharmaceutical, food, cosmetic and household chemical industries, offering versatility in handling a wide variety of packaging types.

The machine enables precise filling of bottles with both liquids and substances of paste consistency. The filling process is characterised by high fluidity and accuracy, ensuring repeatable results with each production run. Once filled, the machine automatically proceeds to the plugging and capping stages, eliminating the need for manual operator intervention.

Production process

The entire production process, from bottle feeding, filling, plugging, capping to the final product, is fully automatic under the control of the integrated operating system. Such a solution not only increases production efficiency, but also minimises the risk of human error and ensures consistent quality of the final product.

The standard configuration of the machine is equipped with 16 container holders to optimise the production process and maintain high productivity. The modular design of the entire machine allows the configuration to be adapted quickly and conveniently by adding or removing individual functional modules.

Advanced technical solutions

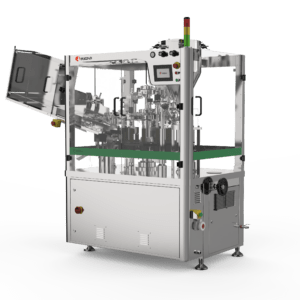

The tube maker is distinguished by a number of innovative technical solutions that ensure its reliability and precision. The machine's indexing function is based on a mechanical drive, which guarantees the stability of this process under different production conditions.

Filling and capping technology

The filling process is carried out using a servo-driven pump. Such a solution allows filling volume parameters to be set conveniently and quickly, resulting in stable and reliable dosing accuracy. Filling precision is a key element in industries requiring strict control over the amount of product dispensed, such as pharmaceuticals and cosmetics.

The packaging is screwed on using a servo motor that effectively controls the tightening torque. This allows the twisting force to be perfectly matched to different types of packaging and caps, preventing damage or inadequate protection.

Compliance with GMP standards

The parts of the machine in direct contact with the material to be dispensed are made of 316L stainless steel and ceramic. The choice of these materials is no accident - they ensure the highest level of cleanliness and hygiene, fully complying with GMP (Good Manufacturing Practice) specifications. This is particularly important in the production of pharmaceuticals, foodstuffs and cosmetics, where process hygiene is of fundamental importance.

Key benefits of the device

The modular design of the tube maker allows for easy adaptation to changing production needs, providing flexibility and the ability to grow the production line in the future. High filling precision (±1%) minimises material loss, which is particularly important when working with costly substances such as pharmaceuticals or luxury cosmetics.

GMP compliance through the use of high-quality materials, such as 316L stainless steel, enables the machine to be used in industries with strict hygiene requirements. The servo motors used in the filling and capping processes ensure precise control over production parameters, resulting in reproducible quality of the final product.

The investment in the presented industrial tube maker represents a strategic step towards modernising and optimising production processes, offering a significant competitive advantage by increasing productivity, improving quality and reducing operating costs in the long term.

Key features

- High production capacity - 2100-2400 tubes per hour (adjustable)

- Precise filling control - accuracy of ≤±1%

- Versatile - handles tubes from 20 to 60 mm in diameter and up to 150 mm in length

- Capacious tank - with a volume of 40 litres

- Pneumatic tube feeding - by means of a vacuum device

- Intelligent temperature control system - for optimum seal quality

- Built-in photocell - allows operation with smooth and printed tubes

- Compact dimensions - 2466(L)×1940(W)×1853(H)mm with a weight of approx. 600 kg

Why choose Tarpak tubing machines?

When you choose solutions and tubing machines from Polish packaging machine manufacturer Tarpak, you gain:

-

Local service and technical support - rapid response and support throughout the country

-

Industry experience - long-standing presence on the market and specialisation in packaging machines

-

Competitive prices - value for money

-

Customisable solutions - adaptation of machines to specific customer needs

-

A qualified team - professional advice and service at every stage of cooperation

-

Innovative solutions - state-of-the-art technology to ensure reliability and precision

Tarpak is a company with tradition, operating in the market since 2005, which has established itself as a distinguished manufacturer of packaging machines. By choosing tubular machines from this brand, you not only get a high-quality machine, but also comprehensive support at every stage of cooperation.

The company provides a full service - from the delivery of the machine, to the installation and training of personnel, to the provision of an efficient service. With a skilled and experienced team, Tarpak also offers customisation of machine configurations to suit each customer's individual needs.

Tarpak tubing machines stand out in the market for their reliability and precise operation, which translates into a long service life of the machines and high quality of packaged products. The company relies on innovative solutions so that its machines are always in line with the latest trends in packaging process automation.

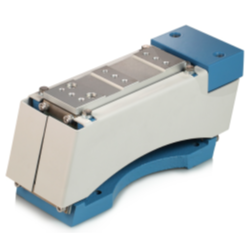

NTL 650B linear vibrator base

NTL 650B linear vibrator base