Counting and packaging lines

Checkweigher

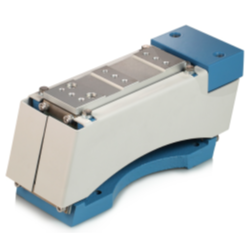

We present you with a cost-effective solution for improving the quality of your packing plant with the TARPAK checkweigher.

Background information

Checkweigher is used to check the correct filling of packaging. The scale, thanks to its precise measuring system, enables the weight of each pack to be checked accurately, defective products to be detected and removed from the production line.

When is it worth using a checkweigher?

Every production process needs to be controlled. Packaging is a process in which errors and shortcomings cannot be completely eliminated. The use of weighing quality control for each package enables the elimination of defective pieces from the production line. The use of Tarpak's automatic checkweigher enables quality control to be significantly faster than manual work, and also eliminates the risk of employee error.

Operating principle

The checkweigher weighs the weight of a package placed on the pan. The checkweigher controller decides on the basis of pre-programmed weight threshold values whether to place the package in the correct or defective product group.

Programming the weight threshold values is very simple. All you need to do is weigh the finished product on the scale and then determine the lower threshold (too little) and the upper threshold (too much) based on its weight. Packages with a weight between these thresholds will be considered correct, while packages too light and too heavy will be rejected as incorrect.

Key features

- The scale's stainless steel scales are resistant to wear and tear, easy to maintain and provide high aesthetics for many years of use.

- The welded steel frame ensures high stability and durability of the structure.

- Adjustable levelling feet make it easy to level the scale.

- High-resolution measuring system to 0.05g.

- A high-speed sorting system ensures high productivity.

Benefits of use

- Highly accurate control of each product.

- Effective elimination of defective pieces.

- Elimination of mistakes made by workers performing manual sorting.

- Inspection of pre-packaged or pre-packaged products.

- Increase in product quality.

- Reducing complaints from customers.

- Minimise the space required for a quality control station.

SDVC31-XL controller

SDVC31-XL controller  NTL 650B linear vibrator base

NTL 650B linear vibrator base