Counting and packaging lines

Counting and packaging lines

Advanced packaging and counting lines and automatic packaging machines

Our counting and packaging lines are designed according to individual customer preferences and for a specific product. The most common counting and packaging line consists of a charging magazine with a product feeder, a vibrating bowl, a mini conveyor, counting sensors and vertical packaging equipment. Each line can also be equipped with additional components such as indexing conveyors, checkweighers, printers, an automatic vibrator controller with vibration sensor and other packaging systems.

Packaging

The packaging process begins with the filling of the backfill magazine. From there, the components are fed into the vibrating bowls and then fed onto the in-line minitransporters. The vibrating bowls are equipped with filling sensors that continuously monitor how full they are.

Counting

Item counting takes place at the end of the linear conveyor with a light curtain. The counted parts are packed into plastic bags. The size of the pouch, the rate at which the parts drop into the pouch and the type of sealing can all be adjusted. The finished pouches with the deducted parts can be transported for further packing. Line control is based on PLCs from the German company SIEMENS and software from TARPAK. In this way, our packaging lines significantly contribute to optimising the time needed to pack small products correctly.

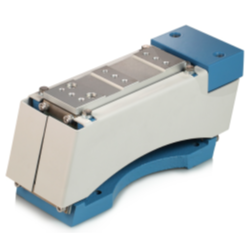

SDVC34-UR controller with automatic adjustment

SDVC34-UR controller with automatic adjustment  NTL 650B linear vibrator base

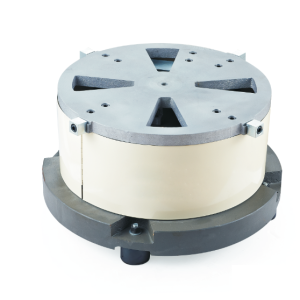

NTL 650B linear vibrator base  Vibration base NTB-46

Vibration base NTB-46  Right-hand bowl S-300-35

Right-hand bowl S-300-35