Metalworking is the backbone of modern manufacturing: from small precision components to packaging machine prototypes, right through to high volume parts for automotive and aerospace. As an engineer, I look at it not only through the prism of "how to make something", but above all "why choose this method": which material properties we obtain, how long it will take the process itselfwhether it will provide high quality and repeatability dimensions. Below you will find a practical guide to types of metalworking - from metal machining, by plastic processing i heat treatment of metalsto finishing and special techniques.

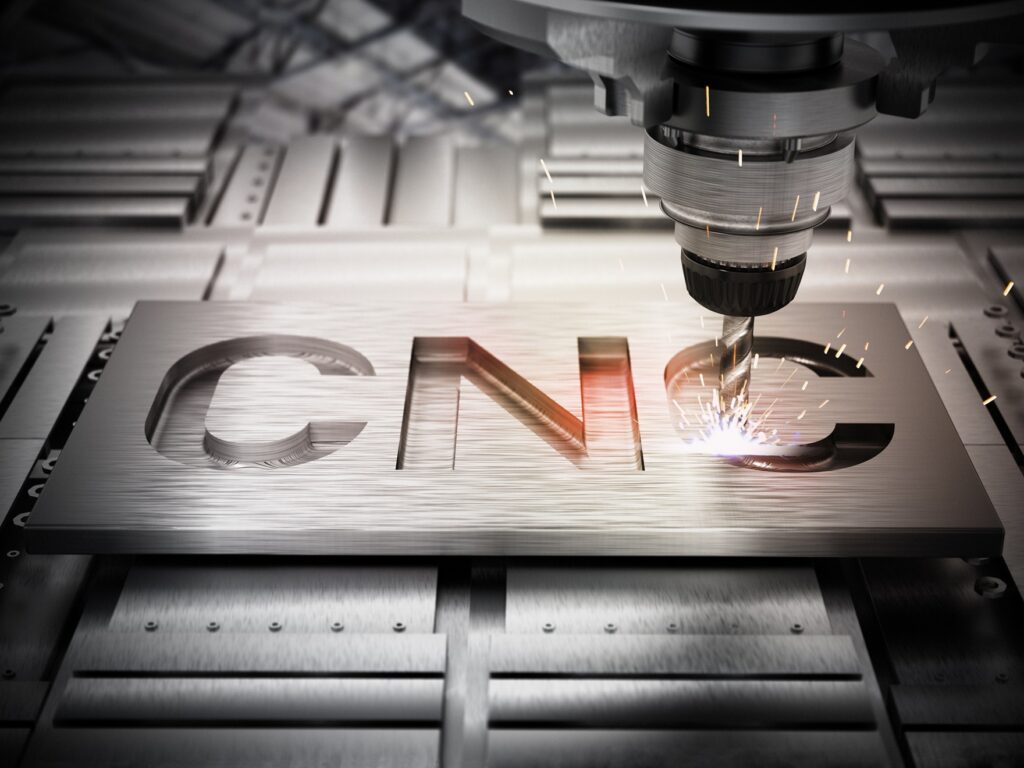

CNC machining: when shape, tolerances and speed of implementation matter

Metal machining via removal of material (subtractive) is the most versatile in production of parts o specific shapes i different shapes: from prototypes to small- and medium-volume series. CNC machines (from Computer Numerical Control) use numerical controlto automatically perform rolling, milling, drilling or finishing of holes. Their strength is precision machining, quick changeovers and the ability to manufacture from a wide range of materials (steel, aluminium, copper, plastics).

In practice, you will most often encounter CNC milling i CNC turning. Milling machines move the tool in three (or more) axes, and the rotation performs the cutter; this is ideal for planes, pockets, threads and complex 3D surfaces. On lathes/turning centres, on the other hand material (rod, bushing) rotates and the tool remains static - hence the outstanding efficiency with axisymmetric workpieces: shafts, bushings, flanges. Today, hybrids are common: lathe-milling centres with driven tools, Y axis and counter-spindle.

If you want to delve deeper into specific tolerances, machining strategies (HPC/HSM), tool selection and tooling materials, it is worth looking at the service providers' practical guides. See also the description of CNC technology on CNC machining - You will find a cross-section of the processes and capabilities of our machine park, making it easier to choose the right method under the desired shape and tolerances.

Forming: forming without loss of material

Plastic processing consists of metal forming through permanent deformations - without chips. This is usually the best choice when you need better mechanical properties (continuous fibre, favourable grain arrangement) and high performance for the series. For basic types credit rolling, forging, metal stamping (stamping), metal bending, drawing and extrusion. Rolling is excellent for strapping and sheets o thin; forging (cold, hot, warm) builds up the strength of shafts, connecting rods or rims; embossing and punching is the fast track to hundreds of thousands of repeatable sheet metal parts; bending closes the process of forming sections and enclosures.

Choosing type of metal forming, follow:

- (1) geometry (flat/tape vs. solid),

- (2) the required durability i hardness,

- (3) cost of tools (punches, dies, dies),

- (4) volume (pressing and drawing pays off with large series).

For thin-walled parts with complex geometries, progressive dies with spring-back control offer excellent repeatability dimensions i surfaces.

Heat treatment of metals: conscious control of microstructure

Heat treatment - i.e. targeted heating and cooling in high temperature - is used to modify the microstructure of steel (and more) to achieve the required properties: from hardness and resistance to consumption, to impact strength and susceptibility to further shaping. The most important processes include: hardening (rapid cooling from austenitisation), tempering, annealingnormalising, carburising/nitriding (surface hardening) and thermal upgrading (hardening + tempering to the required resistance i hardness). Each has different targets and time-temperature-transition curves.

In practice: after machining elements requiring high quality and resistance to effect of corrosion/ wear are subjected to carburising and induction hardening of the surfaces (e.g. wheel teeth), and the bodies - the annealing relaxing for stabilisation dimensions before final grinding. For aluminium alloys, heat treatment (e.g. T6) increases the strength/weight ratio in aerospace parts. Heat treatment-chemical (e.g. nitriding) produces a hard layer that is resistant to corrosion and fatigue with limited core deformation.

Finishing and abrasive processing: the last micrometres determine durability

When class is key surfaces and a tolerance of h6 or better, enter various methods abrasive machining: grinding (planes, shafts, holes), honing (ultra-low roughness holes), lapping/lapping and superfinishing. The principle is common: abrasive particles (aluminium oxide, silicon carbide, CBN, diamond) collected in a bond or in bulk 'pluck' the material, providing small, controlled defects and excellent geometric performance/texture. In automotive, 'peel grinding' - peripheral grinding with a thin high-speed wheel - is popular, partially replacing the machining at the rollers.

The finishing palette includes blasting processes (micro- and chemical treatment/electrochemical), shot-blasting, vibratory polishing (mass finishing) and surface treatments, e.g. chrome plating or anodising. The choice of method affects not only aesthetics, but also friction, lubricant retention, fatigue crack initiation and resistance to effect of corrosion - Therefore, think about the finishing touches at the design stage.

How to select a process? Short decision map

Technological process stack up from the end: functional parameters and properties (e.g. hardness, modulus, corrosion resistance), then geometry/tolerances, and finally cost and volume. If you need a fast MVP or a short series - choose milling/rolling (low cost of entry, flexibility, short deadlines). As the project matures and volumes grow, consider embossing/bending made of sheet metal or forging/rolling for volumetric details - more expensive tools, but lower unit cost and better mechanical properties. Finally, select heat treatment of metals and finishing (e.g. grinding, chrome plating) to tribological and corrosive requirements.

In R&D projects (e.g. prototypes packaging machines) it makes sense to combine paths: the first iterations in the CNC technologyand, in parallel, in the background, prepare a concept for stamping or forging dies - so that there is a smooth transition from prototype to pilot and series production without changing the functional dimensions and supply chain.

Overview of selected techniques - practical tips

CNC turning

- Application: shafts, bushings, ferrules - axisymmetric geometries.

- Tips: minimise tool overhang; control material run-out; for external threads, match the angle of the blade to the profile; consider an auxiliary spindle for machining the other side in one clamping.

CNC milling

- Applications: plates, bodies, 2.5D/3D pockets, details of sheets o thin (with support).

- Tips: HEM/HSM strategy for stainless steels, AlTiN/TiAlN-coated tools; MQL cooling in aluminium; remember residual machining in corners.

Drilling and finishing of holes

- Application: Precision bores for bearings, oil channels.

- Recommendations: Diameter grading, pre-sinking for screw heads, reaming and honing for IT6-IT7, chip control for deep holes (peck cycle).

Metal bending (sheet metal)

- Applications: enclosures, brackets, electrical cabinets.

- Notes: compensate for elastic return; bending radius dependent on rolling direction; for aluminium choose plastic alloys (e.g. 5xxx series) for small radii.

Metal stamping

- Application: large series of parts with repeatable sheet metal geometry.

- Tips: edge quality depends on punch-to-stamp clearance; manage waste and tape in progressive tools; anticipate in-line lubrication and cleaning.

Forging (dies/hammers)

- Application: highly stressed components: connecting rods, pinions, rings.

- Tips: the choice of temperature (cold/warm/hot) is a compromise between the strength of the presses and the accuracy and material phenomena; keep in mind the allowances for subsequent grinding base areas.

Heat treatment

- Application: control hardness/impact/abrasiveness.

- Tips: after hardening - whenever forgiveness; uniform heating (counteracting gradients) and consistency of CTP curves are key; annealing Stress relief after welding/machining removes stresses prior to the baseline measurement.

Sanding and superfinishing

- Applications: bearing races, piston rods, guides.

- Tips: select the abrasive (Al2O3 for carbon steels, SiC for cast iron/spheroidal cast iron, CBN/diamond for hardened and carbide); control 'overheating' (burning) by parameters and coolant.

Coatings and protection

- Application: Corrosion/tribological resistance.

- Directions: chrome plating hard for low friction and protection; in aluminium consider hard anodising; always assess the effect of the coating on tolerance and reference roughness.

Typical process chains

- Precision machining rotating elements: cutting from a rod → CNC turning (bases) → hardening induction treadmill → grinding shafts → final measurement.

- Aluminium machine body: semi-finished milling → annealing relaxation → finishing milling (pockets/ribs) → finishing of holes (reaming) → hard anodising → fitting.

- Sheet metal detail in large series: strip cutting → embossing progressive → bending final → vibration deburring → corrosion protection coating.

Quality, metrology and manufacturability (DFM)

There is no good machining without good measurement. In practice, plan your inspection at the operation level (sensors, diamond gauges), after the stage (CMM/measuring arm) and at the end (SPC report). Remember process bases - design 'to machine' and 'to measure' base surfaces and add allowances under the grinding. In the DFM, reduce the number of settings (one fixture = one reference), increase the internal radii (less stress on the tool at the milling), choose the right material for the process (e.g. steel for carburising vs. nitriding). This is often a bigger 'cost lever' than feed rate.

FAQ - Frequently asked questions and answers

What are the main categories of metalworking?

The three pillars are: machining (CNC), metal forming (rolling, forging, stamping, bending) and heat treatment of metals (hardening, tempering, annealing). These are often completed by finishing processes (grinding, coatings).

When to choose embossing over milling?

For high volumes of thin-walled sheet metal parts: the higher tooling costs will pay off with lower unit costs and excellent repeatability dimensions. For prototypes and small series - CNC milling will be faster and cheaper to start.

Does heat treatment always increase hardness?

No. Annealing reduces hardness and stresses, forgiveness after hardening balances the brittleness and hardness. The choice of process depends on the target properties and applications.

How to improve dimensional stability after treatment?

Enter annealing relax between operations, limit the number of settings (fewer fixings), plan the grinding end bases and monitor the temperature during the measurements.

What does abrasive machining offer over turning/milling?

Micrometer control over roughness, waviness and IT6-IT5 tolerances, less risk of 'stepping stones' and higher durability of friction pairs. It is the "last micrometres" that often determine the performance of bearings/seals.

Where to find practical data on CNC capabilities?

In industry guides and on the websites of service providers - e.g. the CNC machining.

SDVC34-UR controller with automatic adjustment

SDVC34-UR controller with automatic adjustment