What does the production of cardboard packaging involve?

Cardboard packaging is one of the most popular solutions used in many industries. They are characterised by their light weight, strength and ease of processing, making them an ideal choice for manufacturers. The production of cardboard packaging takes place in advanced facilities that use specialised machinery and technology.

How does the production of cardboard packaging work?

Cardboard packaging production process

The carton production process usually starts with the delivery of raw materials, such as paper and cardboard, to the production facility. The raw materials are then subjected to specialised processes, such as milling, mixing and moulding, in order to obtain the appropriate shapes and sizes.

Once the appropriate sheets of cardboard are obtained, they are subjected to further processing steps such as printing, cutting and folding. Cardboard packaging manufacturers are often supported by advanced machines, such as cartoners, which automatically fold and glue the cartons together, ensuring a fast and precise production process.

Automation of the packaging process

Automation plays a key role in the production of cardboard packaging. Advanced control systems and robotics enable automated packing in cartons, labelling and palletising of products. This makes it possible to achieve greater efficiency and precision, while minimising the risk of errors and damage.

Use of cardboard packaging

Cardboard packaging is widely used in many manufacturing plants and beyond. The best example is the food industry, where cardboard packaging is used to store and transport food, ensuring its freshness and protection from the elements. In the e-commerce sector, on the other hand, cardboard boxes guarantee the safe delivery of products and offer the possibility of personalisation, which contributes to brand recognition. Cardboard packaging also plays a special role in transport and logistics, as it is lightweight, which translates into lower transport costs, and it is also easy to store. Furthermore, they are a popular choice due to their biodegradability and recyclability.

Benefits of cardboard packaging production

Cardboard packaging production process

The carton production process involves several key steps. Below are the basic steps in the process.

- Raw materials for production

Three main ingredients are needed to produce cardboard packaging: cellulose, adhesives and inks. Cellulose comes from wood or recycled paper and is the basic component of cardboard. Adhesives are used to glue the different layers of cardboard together and paints are used to add colour and pattern to the packaging.

- Cutting and forming of cardboard

The first step in the production of cardboard packaging is to cut the cardboard into the appropriate sizes. The cardboard sheets are then formed using specialised machines to give them the right shape.

- Folding and sealing the carton

Cardboard packaging, unlike other types of packaging, is relatively simple to fold and glue. Various folding techniques are used, such as the use of grooves, tabs or locks. These elements ensure the durability and stability of the packaging, which is extremely important when transporting and storing products.

- Printing on packaging

An important stage in the production of cardboard packaging is printing on its surface. This can include product information, brand logos, instructions for use or advertising graphics. Printing can be carried out using various techniques such as screen printing, flexographic printing or offset printing.

Advantages of cardboard packaging

Cardboard packaging has many advantages that contribute to its popularity in the market. Here are some of the main benefits associated with their use:

- Ecology and environmental care

One of the key advantages of cardboard packaging is its environmental friendliness. Cardboard is largely a product of plant origin, which makes it more environmentally friendly than packaging made from plastic. Furthermore, cardboard is a fully renewable raw material and the production process can be carried out in a sustainable manner.

- Multifaceted design and personalisation

Cardboard packaging offers great scope for personalisation and customisation. Thanks to various printing and finishing techniques, they can be given a unique look that makes the product stand out on the shop shelf. In addition, cardboard packaging can come in a variety of shapes and sizes, allowing you to tailor it to your specific needs and requirements.

- Low price

Cardboard packaging is relatively cheap to produce, especially when compared to other packaging materials such as metal or glass. This makes them an attractive solution for many entrepreneurs, especially those running smaller businesses.

- Ease of recycling

Cardboard is a material that can be easily recycled. Cardboard packaging, when properly recycled, can be reused for new packaging or other paper products. This contributes to waste reduction and environmental protection.

- Use of cardboard packaging

Cardboard packaging is widely used in a variety of industries and sectors. They are commonly used to package food, beverages, cosmetic products, pharmaceuticals, electronics, household goods and many other goods. Cardboard packaging is ideal for storing and presenting products on shop shelves, as well as for shipping and transport.

Cardboard packaging production: challenges and trends

Use of carton erectors and carton sealers

One of the major trends in the production of cardboard packaging is the increasing use of cartoners. Cartoners are specialised machines that automatically fold and glue cartons together, speeding up the production process and minimising errors.

Innovations in carton packaging

In today's world, innovations for carton packaging are constantly emerging. Examples include smart labels that allow products to be tracked and monitored and special coatings that protect the packaging from moisture, UV radiation and other external factors.

Summary

The production of cardboard packaging is a complex process that requires advanced technology and expertise. Cardboard packaging is widely used in a variety of industries and offers many benefits such as environmental friendliness, durability, aesthetics and ease of use. There are also trends in cardboard packaging production, such as the use of cartoners and packaging innovations. When choosing a carton packaging manufacturer, it is worth considering experience, reputation, technology and customisation.

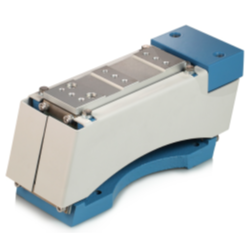

NTL 650B linear vibrator base

NTL 650B linear vibrator base