Packaging machines for bulk products: automating the packaging process

Packaging of bulk products is a key part of production in many industries. Products such as grains, powders, sugar or coffee require precise and efficient packaging to preserve freshness, avoid product loss and meet quality standards. To this end, bulk packaging machines are increasingly being used to revolutionise the process. In this article, we take a look at how these machines work and why they are indispensable in the service packaging of bulk products.

Automation of the packaging process

Packaging machines for loose products is a device that automates the packaging process of products such as coffee, flour or rice. It works on the principle of rotary gearing, where the product is moved through the machine and then packaged in a suitable manner. By automating this process, many benefits can be achieved.

How does a bulk packaging machine work?

Feeding the product: The process starts with feeding the product into the machine. This can be done manually or via a conveyor system - feederwhich delivers the product to the device.

- Measurement and dosage: The machine is equipped with a measuring system that accurately measures the amount of product to be placed in the packaging. This is crucial to ensure that each pack contains the correct amount of product.

- Packaging formation: The machine then forms the packaging from a material, such as film or paper. The packaging can be of different sizes, depending on the manufacturer's needs.

- Filling the pack: The product is accurately filled into the packaging. This is where precision and accuracy are key, as errors in product quantity can lead to financial losses and quality problems.

- Packaging closure: Once the product is filled, the packaging is sealed, often using a welder or adhesive. This ensures that the product remains fresh and is not exposed to the elements.

- Marking and labelling: In the final step, the packaging is often marked with an expiry date, serial number or other information. It is then labelled and ready for distribution.

Why invest in bulk packaging machines?

1. Efficiency and time saving

Automatic packaging machines for loose products work much faster than manual packing. This saves time and increases production efficiency. When the process is automated, one machine can handle many packs per minute.

2. precision and quality

Automatic packaging machines are precise in dosing the product, which eliminates human error and ensures consistent packaging quality. This ensures that the product is attractive to customers and meets quality standards.

3. cost savings

Although the investment in packaging machines may be costly initially, it leads to savings in the long term. Fewer product losses, fewer workers needed for packaging, and increased production translate into lower costs.

Service packaging of loose products

Packaging machines for bulk products are not just used in captive production. The increase in demand for service-based packaging of bulk products is leading many companies to offer specialised packaging services. This works on an outsourced basis, where a company hands over the packaging process to a professional company that has the right machines and experienced staff.

As a result, companies can focus on their core business and the packaging process is carried out by experts, guaranteeing high quality and efficiency. Service packaging of bulk products is a solution that can bring many benefits, especially for companies that do not want to invest in packaging machinery and personnel.

To sum up, packaging machines for loose products are irreplaceable nowadays. The automation of this process contributes to the efficiency, precision and quality of packaging, as well as helping to reduce production costs. The increase in service packaging of bulk products means that companies can take advantage of these benefits without having to invest in their own machinery. It is therefore worth considering the use of bulk product packaging machinery in your manufacturing operations.

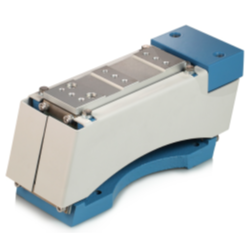

NTL 650B linear vibrator base

NTL 650B linear vibrator base