When entering a pharmacy, supermarket or electronics shop, at almost every turn we encounter a packaging, The blister pack is one of the most popular and versatile packaging solutions in the industry. We are talking about blister packaging - one of the most popular and versatile solutions in the packaging industry. What exactly are blister packs, How do they come about and why have they gained so much trust from manufacturers in various sectors? In this article, we will answer all highlights questions.

What is blister packaging?

Packaging type blister is a type of packaging consisting of two key elements: a shaped „pocket” with a plastics and a back closure layer, usually made of cardboard, aluminium foil or other plastic. A distinctive, transparent form is created in the thermoforming technology, which involves heating the sheet films (e.g. PET or PVC) and giving it the desired shape using a mould. In this way, the packaging is perfectly adapted to the shape and size of the product - from small tablets for a set of screwdrivers.

This design not only perfectly protects the contents, but also allows the customers for a thorough inspection of the goods before purchase, which is an invaluable marketing advantage. Blisters are now a key element of product strategy in many industries, and their versatility makes them one of the most popular packaging choices. However, it is worth remembering that this is just one of many solutions available on the market. For a full overview of the possibilities, from films to cartons, see our comprehensive article discussing types of packaging.

Types of blisters - which solution to choose?

Although the overall concept of the blister is simple, there are a few basic types of blisters, which vary in terms of closure and design. The choice of the right variant depends on the specific product, safety requirements and marketing strategy.

- Sealed blister - is the most common type, in which the plastic mould is permanently sealed to the cardboard back. This process provides a very strong and durable seal, protecting the product from theft, moisture and mechanical damage. It is ideal for packaging electronics (batteries, inks for printers), building accessories (screws) or cosmetics.

- Folded blisters (slip-on) - in this solution, the edges of the plastic mould are folded on three sides, creating a pocket into which the cardboard box is inserted. This option is less durable than sealing, but has its advantages - it allows easy opening without destroying the of the total packaging. Often used for packaging products that the customer may want to see up close, such as office supplies (pens) or certain toys.

Key benefits of blister packaging

The popularity of blister packaging is due to its numerous advantages. First and foremost, they offer an unparalleled level of protection. Rigid, profiled the plastic mould effectively protects the product from impacts, crushing and shocks in the transport and on the shop shelf. In the case of packaging of medicines The airtight seal guarantees sterility and protection from external factors.

Transparency is another advantage. Being able to see the product builds confidence and facilitates the purchase decision. The cardboard backing, on the other hand, provides an excellent surface for graphics, product information and the key data it contains product label. This combination of visibility and information space makes the blister a powerful marketing tool.

Wide range of applications in various industries

Versatility is the word that best describes blister packs. Their use of is extremely wide and covers virtually every sector of the market.

- Pharmaceutical industry: This is where blisters are standard in packaging of medicines, ensuring precise dosage, hygiene and information on expiry dates.

- Cosmetics industry: Cosmetics such as lipsticks, creams, masks or artificial eyelashes are often packaged in blister packs that enhance their aesthetics and protect their delicate contents.

- Consumer goods: From batteries to light bulbs to small electronic accessories.

- Automotive and DIYThe blister packs are ideal for packaging spare parts such as doormats automobiles, as well as small parts such as screws, nails or dowels.

- Office supplies and toys: Pens, markers, small sets of bricks or figurines.

Implementation of such diverse projects, tailored to specific requirements product and volume, requires advanced technology. Efficient process production and large-scale packaging is only possible through the use of modern, automated lines. Specialised packaging machines for thermoforming, filling and blister sealing are the key to achieving reproducible quality and optimising costs, whether production volume is small or mass.

Bottom line - is the blister the solution for you?

blister packs is an extremely functional, aesthetically pleasing and cost-effective solution that meets the needs of many industries. They provide excellent securing the goods, great exposure in points sales and extensive branding opportunities. Before making a final decision and submitting orders please however, carefully analyse the specifics of your product - its shape, weight, protection requirements and target group.

blister packs is an extremely functional, aesthetically pleasing and cost-effective solution that meets the needs of many industries. They provide excellent securing the goods, great exposure in points sales and extensive branding opportunities. Before making a final decision and submitting orders please however, carefully analyse the specifics of your product - its shape, weight, protection requirements and target group.

If you are wondering how to effectively and safely package its products, the blister is certainly an option that worth considering.

FAQ - Frequently asked questions

What materials are the blisters made of?

The most commonly used plastic for pocket formation is PET (polyethylene terephthalate) or PVC (polyvinyl chloride) film due to their rigidity and transparency. The closing layer is usually printed cardboard, aluminium foil (for medicines) or another plastic film.

Is blister packaging environmentally friendly?

Increasingly, recycled materials (e.g. R-PET) are being used for the production of blisters. The recyclability of the finished packaging depends on local segregation systems. The need to separate the plastic from the paper can be a problem, but more and more mono-material solutions are emerging on the market to facilitate this process.

What is the main difference between a welded and folded blister?

The main difference lies in the method of closure and the level of security. Sealed blisters are permanently sealed, providing excellent protection against opening and theft. Folded blisters allow the carton to be easily ejected without destroying the packaging, which is useful when the customer wants to see the product up close before buying.

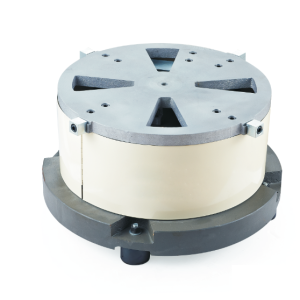

Vibration base NTB-46

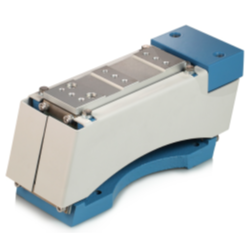

Vibration base NTB-46  SDVC34-UR controller with automatic adjustment

SDVC34-UR controller with automatic adjustment  Right-hand bowl S-300-35

Right-hand bowl S-300-35  NTL 650B linear vibrator base

NTL 650B linear vibrator base