The statistics are unforgiving - according to CSO data, there has been an increase of around 6% of freight transported by Polish transport companies since 2018, with 68% of cases where damage and quantitative errors in goods are due to the shipper's oversight. Today, pallet transport is the backbone of modern logistics, but its effectiveness depends largely on the correct securing of cargo. Proper pallet securing minimises the risk of damage to goods and ensures the safety of the entire transport process.

Fundamental methods of securing pallets

Pallet transport requires the use of proven securing techniques to ensure that the load remains stable throughout the journey. Common methods include the use of stretch film, conveyor belts and protective corners. Modern packaging machines are revolutionising the process, offering not only increased efficiency, but also repeatability and precision protection. By automating the packaging process, human error, which statistics show to be the main cause of transport problems, can be significantly reduced.

Proper preparation of the pallet itself before loading is also key. It is a good idea to check the condition of the pallets before transporting them to ensure that they are in good condition and have no damage. Pallets with cracks, broken boards or loose nails can be dangerous and cause accidents. Standard Europallets (EPAL) with dimensions of 120×80 cm and a strength of up to 1500 kg are the basis of the European transport system.

Stretch film wrapping - the most popular method

Stretch film wrapping remains the most popular method of securing palletised loads, providing stability and protection against moisture, dust and contamination. Modern pallet wrappers offer a variety of technological solutions adapted to specific needs. Disc wrappers, where the pallet spins on a rotating base, are some of the most common machines in warehouses and logistics centres. Alternatively, arm wrappers, where the pallet remains stationary and the machine arm rotates around it - ideal for unstable and heavy loads.

The wrapping process requires certain rules to be followed. Start by securing the base of the pallet, making at least two full laps to properly anchor the film. Then continue wrapping upwards, maintaining the 50% of applying successive layers of film. The key is to maintain enough tension in the film - enough to stabilise the load, but not so tight as to damage fragile products.

Alternative security methods and the role of cartoners

In addition to traditional stretch wrapping, there are other effective methods of securing pallets. The use of polyester or composite strapping can further enhance the stability of loads, especially those that are heavy or prone to shifting during transport. Strapping can be used on its own or in combination with wrapping, with security provided by equipment adapted to conditions of a specific strength.

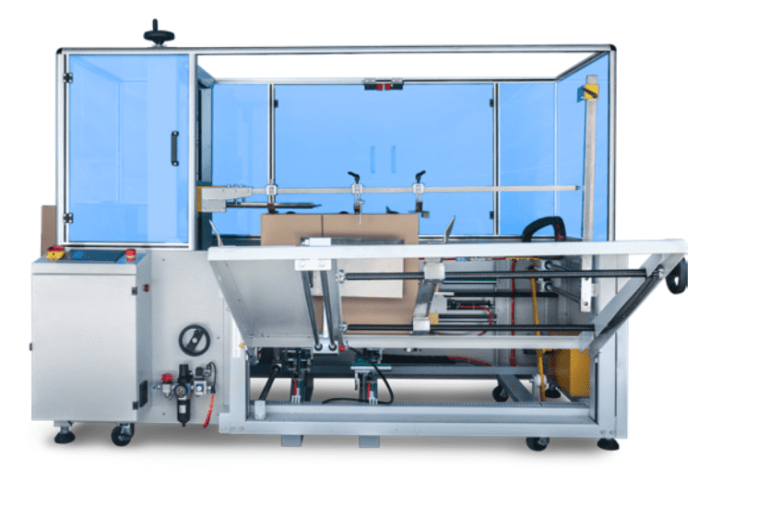

The following also play an important role in the cargo preparation process cartonerswhich enable products to be professionally packed into master packs before being placed on pallets. The basic task of cartoners in the packaging process is to pack packages or sets of pre-packed products into a master carton. Modern packaging lines integrate case packers with systems for palletisation, creating end-to-end logistics solutions from packaging the product to securing it on the pallet.

Legal responsibility for securing pallets

The issue of responsibility for the proper securing of pallets in transport is strictly regulated by law. According to Article 43 § 1 of the Transport Law, the obligation to secure the pallet lies with the consignor and the consignee, although there are contracts in which this task is delegated to the carrier. The carrier is responsible for the course of the transport and is obliged to check that the goods have been correctly stowed on the pallet. The driver should inspect the goods very carefully and may even require the goods to be unpacked, although this right is usually not exercised.

In practice, the carrier may refuse transport if it considers that adequate security measures have not been taken. Only transport packaging with seals affixed by the shipper can effectively exempt the carrier from liability for quantity shortages. In the case of international transport, the CMR Convention applies, and for matters not regulated by the Convention, the Transport Law applies.

Best practice for securing pallets

Effective pallet securing requires following proven practices. The heaviest loads should be at the bottom and the lightest loads at the top, with nothing overhanging the edges of the pallet. Load stacking remains the most commonly used method of preparing goods on pallets, but not all materials can be stacked in this way.

The use of protective angles and edges provides additional security, especially for fragile goods. It is a good idea to cover a properly loaded pallet with special shrink film hoods with UV protection additives to shield the cargo from the weather. Labelling pallets with visible information about the goods makes it easier for warehouse staff and drivers to identify shipments.

Summary

Securing pallets in transit is a complex process that requires attention at every stage - from choosing the right pallet, to the correct placement of the goods, to the use of appropriate securing methods. Investing in modern packaging technologies and following proven practices not only minimises the risk of loss, but also increases the efficiency of the entire supply chain. Remember that a properly secured pallet not only protects the goods, but also the safety of all participants in the transport process.

FAQ - Frequently asked questions and answers

Who is responsible for damage to the goods on the pallet during transport?

Answer: According to the Polish transport law, the obligation to secure the pallet lies mainly with the shipper and the consignee. The carrier is responsible for the course of the transport and must check the correct positioning of the pallets, but is not responsible for securing the cargo, unless otherwise stated in the contract. In the case of damage, it is crucial to prove whether adequate securing measures have been applied.

What are the most important mistakes when securing pallets?

The most common errors are: incorrect weight distribution (heavy items on top), insufficient stretch film tension, failure to check the condition of the pallet before loading, leaving items sticking out beyond the edges of the pallet and incorrect stacking of loads. Statistics show that 68% of the problems are due to oversights at the loading stage.

Can a pallet be transported without stretch film?

Yes, there are alternative securing methods such as securing straps, protective angles or shrink hoods. The choice of method depends on the type of goods, transport conditions and customer requirements. However, stretch film remains the most popular solution due to its versatility, low cost and ease of application. Regardless of the method chosen, the cargo must be properly stabilised.