A modern production line is a complex system that combines advanced technologies, precisely selected machinery and appropriate software. The efficiency and reliability of such a line translates directly into reduced production costs, increased productivity and improved quality of the finished product. To achieve these goals, companies are increasingly relying on automation and the use of modern control systems.

How does a production line work? What technological solutions are used in modern plants? What steps should be taken to optimise production processes? In this article, we outline the best ways to improve efficiency in mass production.

What is a production line?

A production line is an organised arrangement of machinery, equipment and control systems that together enable raw materials to be transformed into finished products. With the right configuration and the use of automation, it is possible not only to increase productivity, but also to maintain high quality and repeatability of products.

In the food industry, production lines are used to process meat, bread, beverages and other foodstuffs. In the automotive industry, they are used to assemble components, weld structures and paint car bodies. In the electronics industry, on the other hand, they are responsible for assembling small components, testing finished products and packaging them. Each production line is designed with a specific industry in mind and therefore differs in terms of the equipment and technologies used.

Types of production lines

Production lines can be divided into several main categories depending on the degree of automation, the application and the type of raw materials processed.

✅ Manual lines - are mainly based on human labour, with machines only supporting production. They are used in plants where precision and manual quality control are crucial.

✅ Semi-automatic lines - use both operator labour and automatic equipment such as conveyor belts, depalletisers and carton sealers. This is an intermediate solution between full automation and traditional manual production.

✅ Automated production lines - equipped with transport systems, control computers and advanced machinery such as carton machine and vision systems. They allow high process repeatability and minimise human error.

The selection of a suitable production line depends on the specific characteristics of the company, the type of raw materials processed and the expected scale of production. Automation is particularly beneficial in mass production, where increasing productivity and reducing unit costs are key.

Construction and operation of a production line

A modern production line consists of many components that work together to transform raw materials into a finished product.

Line components

🔹 Processing machinery - responsible for processing raw materials, e.g. mixing ingredients, cutting, moulding or welding.

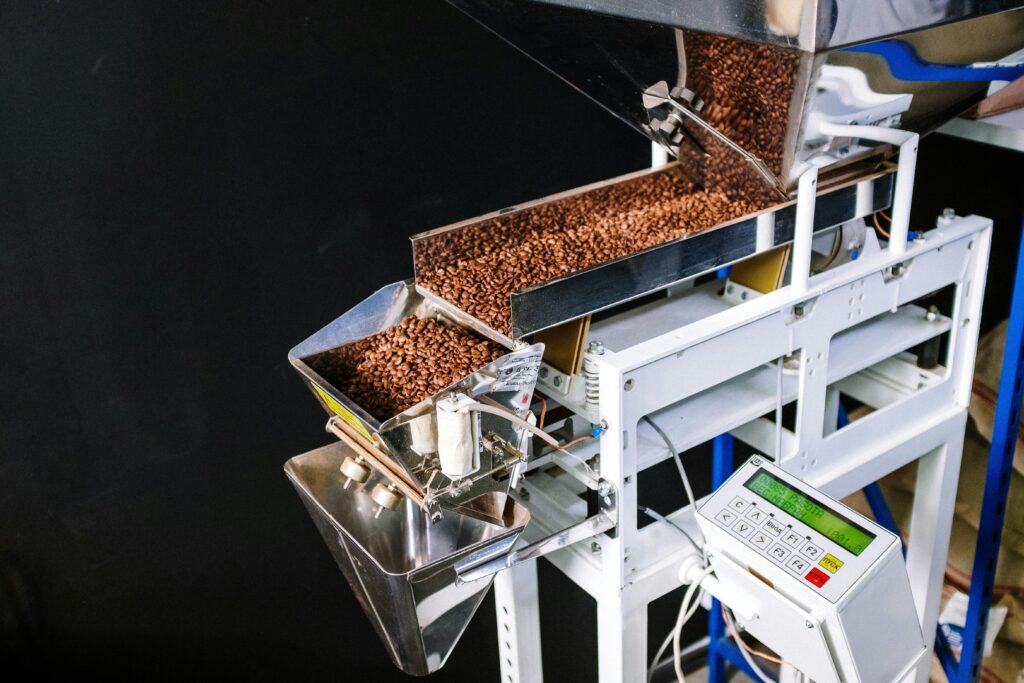

🔹 Transport systems - Screw conveyors and belt conveyors enable materials to be moved smoothly between production stages.

🔹 Packaging machines - responsible for the last element of production, namely product packaging into boxes or cartons, and palletisation of cartons.

🔹 Control systems - computers that control process parameters, ensuring precise dosing of raw materials and optimisation of the production cycle.

Software and IT systems

Modern lines use advanced IT systems that integrate production with other company departments. MES software allows key performance indicators to be monitored and vision systems enable automatic quality control.

With these solutions, companies can react faster to market changes, eliminate downtime and ensure repeatable production.

Optimisation of production processes

In order for a production line to operate as efficiently as possible, it is necessary to optimise it on a regular basis. This process involves both technological analysis and the implementation of modern control systems.

Optimisation methods

🔹 Process analysis - identifying where there are losses of raw materials, excessive downtime or quality problems.

🔹 Automation of key stages - the introduction of modern machines and robots that eliminate human error and reduce production time.

🔹 KPI monitoring - constant monitoring of performance, allowing a rapid response to any deviations from the norm.

By implementing these methods, it is possible not only to increase productivity, but also to reduce raw material consumption and production costs.

Efficiency in production - key factors

The efficiency of a production line depends on a number of factors that together affect its performance and reliability.

🔹 Quality of raw materials - processed materials must meet the appropriate standards to ensure a high quality final product.

🔹 Process automation - automated production lines reduce errors and increase the repeatability of production.

🔹 Qualified staff - despite the use of modern technology, experienced operators are needed to oversee processes and respond to potential breakdowns.

Putting the production line into practice

The process of implementing a new production line requires careful planning and consideration of many factors, such as available space, technological requirements and budget.

Implementation challenges

🔹 Investment costs - the purchase of modern machinery such as a depalletiser or a carton sealers, involves high initial costs, but saves money in the long term.

🔹 Integration of systems - the line must be compatible with existing IT systems and plant logistics.

🔹 Staff training - modern lines need to be operated by trained operators, which means specialised courses are required.

Summary

A properly designed and optimised production line allows for increased efficiency, improved product quality and reduced production costs. It is worth investing in modern technologies that enable the automation of processes and ensure high production repeatability. Companies that implement innovative systems gain a competitive advantage and increase their profitability.