Why is product labelling strategic today?

In modern industry product labelling is no longer just a matter of aesthetics, but a real necessity arising from regulations, logistics and customer expectations. Labels contain barcodes, information about the batch, production date, composition or serial numbers., and their correct application translates directly into smooth logistics and sales processes.

Therefore industrial labelling machine is now becoming a standard feature of production line in many sectors of the manufacturing industry - from food and cosmetics to chemicals and logistics.

Marking of goods as part of the overall packaging process

Even at the packaging stage, it is worth thinking about the full process marking of goods, which includes not only application of labels, but also real-time printing of labels and their precise positioning on packaging.

Automatic labellers allow the integration of printing, coding and pasting in one working cycle. This increases productivity, and the risk of operator error is significantly reduced. In practice, this means greater accuracy, speed and repeatability of the labelling process.

What products and packaging can the labellers handle?

Modern automatic labelling machine can be adapted to very different types of products and packaging:

- flat packs (cardboard boxes, trays),

- cylindrical containers i round containers,

- bottles, jars, cans,

- different packaging diameter and height.

Depending on the application, labelling head can apply labels from one or more sides, and feeding systems take into account the type of self-adhesive labels and parameters primer.

This flexibility makes a single solution can handle multiple product formats, which is of paramount importance in a changing production portfolio.

Proper product labelling and regulatory compliance

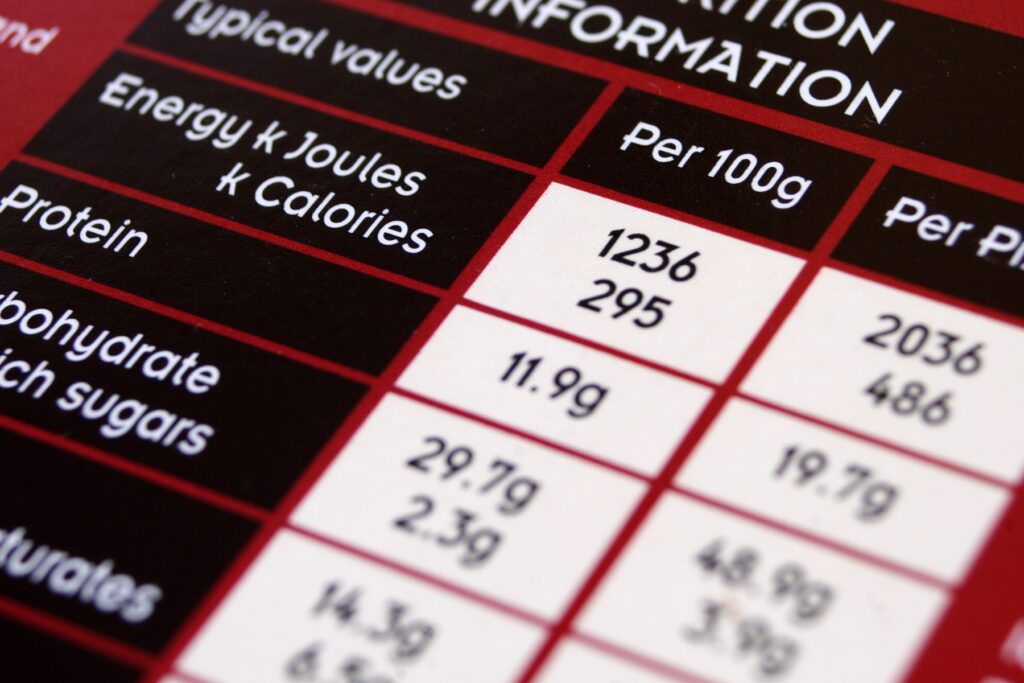

Another key aspect is correct product labelling, which must be:

- readable,

- permanently affixed,

- compliant with applicable industry and legal standards.

This is of particular importance in food and cosmetics industry, where labelling errors can lead to product recalls.

Industrial labellers are therefore often equipped with systems for checking the presence of a label, verifying barcodes and checking print quality. This makes it possible to eliminate defective pieces even at the production stage.

Integration of the labelling machine with other packaging machines

In many plants, labelling is just one step in a larger packaging process, which also involves other machines such as tube maker or carton machine - and their joint operation in a single process line allows manual operations to be reduced and the productivity of the entire line to be maintained consistently.

- tube filler for filling and closing tubes - Once the dispensing and closure of the package is complete, the labeller can automatically apply the label (or print and apply it in real time), ensuring consistent batch labelling and eliminating the risk of manual labelling errors.

- case packer for folding and sealing of master packs - The labeller can label both individual products prior to cartoning and the finished packaging, which facilitates identification in logistics and speeds up picking and shipping control.

Integrating the labelling machine with these devices makes it possible to create a a fully automated line, where every step is synchronised and product flow control can be tied together with a single system (e.g. via PLC communication and sensors). This ensures that labelling does not become a bottleneck and that product flow is smooth and predictable, further reducing downtime and improving quality control along the line.

Automatic vs semi-automatic labellers - which to choose?

Both are available on the market automatic labellers, as well as semi-automatic. The latter are often used at:

- smaller production runs,

- frequent product changes,

- limited investment budget.

However, with larger volumes automation pays for itself quickly, as it provides:

- higher performance,

- less dependence on the operator,

- greater quality repeatability.

Therefore, in growth-oriented production facilities an industrial labelling machine is a long-term investment, which improves efficiency in real terms.

Working in tough industrial environments

Modern equipment is designed to work in difficult industrial conditions, such as:

- dustiness,

- increased humidity,

- fluctuating temperatures.

Robust design, high-performance components reliability and advanced control system ensure that the labellers can operate continuously for many hours.

Intuitive operator panel allows quick conversion to a different label and product format, reducing the downtime during production shifts.

Printing and label application in one cycle

Systems such as print & apply, that enable:

- printing of variable data,

- immediate application of the product label.

This solution eliminates the need to stock finished rolls of labels and allows you to react to changes in orders in real time.

This is particularly important for short runs and personalised products, where it matters flexibility and responsiveness.

Labelling of packaging and pallets in logistics

In the area of logistics, it is also crucial to marking of master cartons and pallets.

Proper logistics labelling:

- make it easier to identify the goods,

- are supported by WMS and ERP systems,

- reduce picking errors.

Labelling machines can be part of production and warehouse management systems, which ensures full data integrity from production to dispatch.

What to look for when choosing an industrial labelling machine?

There are a number of key factors to consider when making a decision:

- type and size of packaging,

- line speed,

- requirements for positioning accuracy,

- the possibility of expanding the system in the future.

Well-chosen industrial labelling machine not only makes it possible to increase performance, but also to improve the quality of labelling and reduce production losses.

From the point of view of long-term efficiency it is worth investing in a scalable solution, tailored to the company's development.

Importance of service and support

Not without significance is also experience of the machinery supplier and access to service and spare parts. Even the most advanced equipment requires periodic maintenance.

Rapid service response minimises downtime, which, in industrial reality, generate high costs and disrupt the production schedule.

Summary - The labelling machine as part of modern automation

Labelling machines are no longer an add-on to the packaging process, but its integral part. The right machine, integrated with the rest of the line's equipment, makes it possible to achieve:

- high efficiency,

- large precision of application,

- stable and reliable production.

In a reality of increasing competition and growing market demands, automation of labelling is becoming not so much an option as a necessity.

FAQ - The most common questions about industrial labellers

Can one labelling machine handle different types of packaging?

Yes, many labellers allow quick changeovers and work with different product formats once the head and guidance systems have been properly adjusted.

When is it better to choose an automatic labelling machine instead of a semi-automatic one?

The automatic labeller will prove useful for high volumes and high line speeds, where process continuity and minimisation of manual work is key.

Can labellers print variable data on labels?

Yes, print & apply systems allow batch numbers, dates and logistics codes to be printed directly before application to the product.