Introduction to automation of production processes

The automation of manufacturing processes is an inevitable change that is revolutionising modern industry. Machines and robots are replacing people in repetitive, precision-intensive tasks. This solution brings many benefits - increasing productivity, improving quality and optimising costs. Automation encompasses all stages of production: from material processing to assembly to quality control and packaging. In addition, production automation optimises processes and reduces human involvement in monotonous tasks, resulting in increased productivity and a cost-effective working environment. The use of packaging machines ensures higher profits and the ability to adapt processes to dynamic changes in the market.

History of the development of automation in industry

The first steps in automation were taken as early as the 19th century, especially in the textile and metal industries. The breakthrough came in the 20th century, when advanced machines began to dominate factories. Since the advance of automation in production processes, today industrial robots and artificial intelligence are present in almost every industry. This has made production processes more efficient, and the implementation of production line automation has enabled increased production rates and quality control at unprecedented levels. Automation and robotisation of processes have contributed to reduced production times and increased precision, eliminating errors due to human labour.

Benefits of automating production processes

Automation speeds up production and minimises errors. Robots do not make human mistakes and operate in a predictable and repeatable manner. Packaging machines such as cartoners whether depalletisers from Tarpak.pl, streamline logistics processes, reducing packaging time and costs. Through the use of industry automation, work efficiency is increased and production lines can be adapted to different types of packaging. The use of industrial robots allows for greater precision in operations, resulting in better quality of final products and reduced losses due to production errors. The automation and robotisation of production processes also leads to more economical management of raw materials and better storage management.

Reducing production costs

Automation of production allows significant savings. Reduced raw material consumption, optimised energy consumption and reduced waste are key factors. Robots work faster and more efficiently than humans, resulting in increased productivity and reduced operating costs. In addition, the automation of production lines reduces human involvement in the monotonous production process, which not only reduces labour costs but also improves safety on the shop floor. The implementation of intelligent management and quality control systems allows for better optimisation of processes, resulting in shorter lead times and less waste.

Improving product quality

Automation eliminates errors resulting from human inaccuracy. Robots operate with millimetre precision, significantly improving the quality and repeatability of products. Intelligent systems monitor quality in real time, which minimises the risk of production defects. By implementing automation in production processes, it is possible not only to increase efficiency, but also to improve quality control at every stage of production. The use of robotisation in industry translates into better alignment of products with market requirements and shorter production times. Industry automation also enables more efficient packaging and preparation of products for transport, which is crucial in the warehousing and distribution process.

Types of robotisation in industry

Modern factories use different types of robotisation.

- Robotisation of assembly - automated production lines reduce assembly times, increasing precision and repeatability.

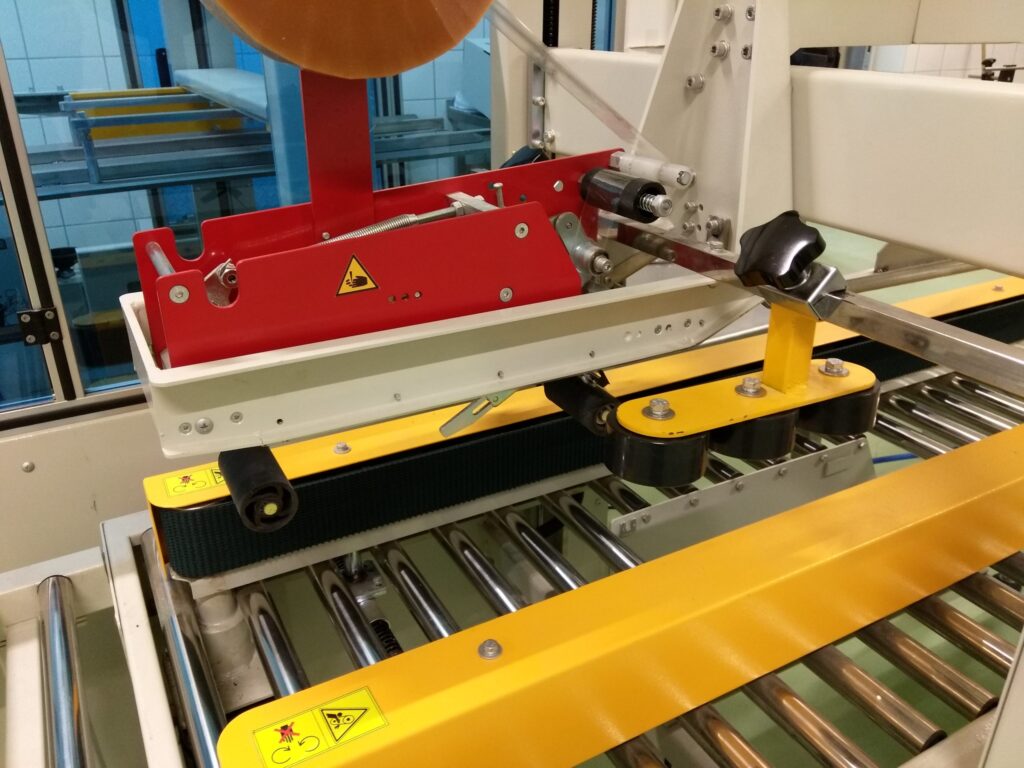

- Robotisation of packaging - modern machinery, such as flow packs from Tarpak.co.ukThey speed up the packaging and protection of products, thus optimising logistics processes.

- Robotisation of transport - autonomous AGVs deliver materials to production lines without human intervention, reducing transport costs and operational time.

How to implement production automation?

Implementing automation requires a detailed analysis. Needs must be identified, appropriate technologies selected and packaging machinesand ensure that staff are trained. Cooperation with experienced solution providers, such as Tarpak.pl, allows the automation process to be carried out effectively. Production automation allows production processes to be better adapted to changing market conditions, which translates into higher profits and increased line efficiency. Properly implemented robotisation of production processes means not only greater labour efficiency, but also the possibility of flexible resource management and optimisation of storage and transport costs.

Support for the implementation of production automation

Support in the implementation of production automation allows for increased productivity, precision and repeatability of production. With the right technical advice and analysis of production processes, it is possible to optimise both production lines and the entire production process. Industry automation requires the technology to be tailored to the specifics of the industry, which is why the support of specialists can significantly accelerate the implementation of appropriate solutions. Support in the implementation of production automation can include an analysis of the company's needs and the type of production. Conducting appropriate audits and tests enables better control of quality and productivity, which translates into tangible benefits in the form of increased productivity and higher profits.