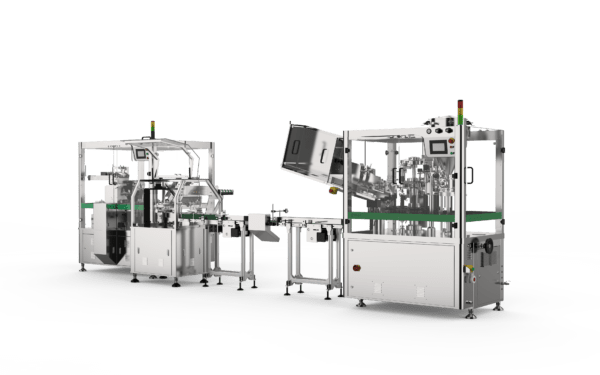

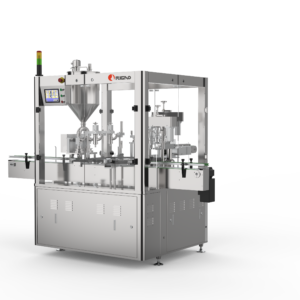

Tuber RGPL-1580A

The RGPL-1580A tube maker is an integrated, fully automated production line combining advanced tube filling and sealing technology with cartoning. The system offers a complete solution for high productivity, precision and GMP compliance, making it the ideal choice for cosmetic, pharmaceutical and food companies looking for reliable packaging systems.

- Product available on request

Production line - Technology and functionality in one

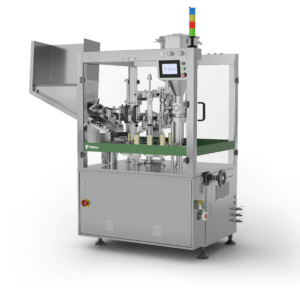

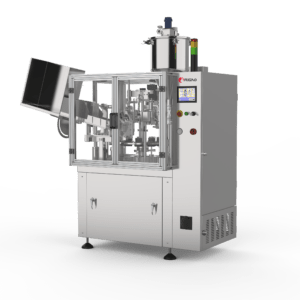

The RGPL-1580A tube maker is an advanced production line that combines a Rigao tube filling and sealing machine with a cartoning system. The entire technological process includes automatic tube feeding, orientation according to markers, precise filling, heat sealing, sealing, coding, trimming and automatic insertion of tubes and information leaflets into carton packs.

The pneumatic tube feeding system ensures exceptional accuracy at every stage of the production process, minimising the risk of errors and downtime. All components in contact with the product are made from 316L stainless steel, guaranteeing cleanliness and full compliance with GMP standard requirements.

The RGPL-1580A tube maker provides a complete solution for companies looking for high-performance and reliable systems for automatic packaging of products in tubes, while ensuring optimised production costs and high quality final packaging.

Technical specifications and functionality

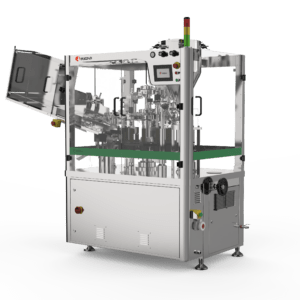

The RGPL-1580A production line is designed for maximum productivity and operational flexibility. The system integrates advanced technological solutions that enable the entire tube filling and packaging process to run smoothly.

Production process

- The entire work cycle of the RGPL-1580A tube maker includes a number of automated steps that ensure precision and repeatability:

- Automatic tube feeding using a high accuracy pneumatic system

- Orientation of tubes according to eye mark for precise positioning

- Filling of tubes with product under strict quantity control

- Hot melt welding and sealing of tubes

- Coding of information on tubes (production date, batch number, etc.)

- Precise trimming of tubes to the required length

- Automatic insertion of filled tubes and information leaflets into cardboard packaging

- The machine's design is based on high-quality components that ensure long-lasting and trouble-free operation in industrial conditions, meeting the highest quality standards.

Key features

The RGPL-1580A tube maker sets itself apart from competing solutions with a range of innovative features and functions:

-

Fully automated process - from tube feeding to cartoning, eliminating the need for manual handling and reducing the risk of human error1

-

High precision filling - a pneumatic system ensures accurate product dosing, minimising material losses1

-

GMP compliance - all components in contact with the product made of 316L stainless steel, guaranteeing hygienic production conditions1

-

Integrated carton system - eliminates the need to purchase and operate a separate packaging machine

-

Advanced process control - marker detection system ensures precise positioning of tubes

-

Production flexibility - adaptable to different tube sizes and product types

-

Optimisation of production space - compact design integrating multiple functions in a single unit

Benefits for your company

The implementation of the RGPL-1580A tube maker in the production process brings a number of tangible benefits:

Time and cost savings

The automated packaging process significantly reduces production time and labour costs, which directly translates into greater productivity and competitiveness for the company. By integrating filling, closing and cartoning functions into a single machine, the need to transport semi-finished products between separate machines is eliminated2.

Improving the quality of the end product

Precise dosing and hermetic sealing of the tubes ensure optimum protection of the product and extend its shelf life. A uniform production process guarantees the reproducibility and high quality of each pack.

Minimising material losses

Accurate dispensing and closing of the tubes significantly reduces product loss during the packaging process. Pneumatic infeed system ensures precise operations at every stage of production1.

Compliance with industry requirements

GMP-compliant design ensures the machine meets the stringent requirements of the pharmaceutical and cosmetics industries, facilitating certification of production processes1.

Increased production flexibility

The ability to quickly switch the machine to a different tube format or product type enables a swift response to changing market needs and customer orders.

Examples of solutions

The RGPL-1580A tube maker can be equipped with a number of additional modules and functions to adapt the machine to specific production requirements:

Cosmetics industry

-

Filling tubes with face and body creams

-

Dosage of masks, scrubs and other skin care products

-

Packaging of conditioners and hair masks

Pharmaceutical industry

-

Production of medicinal ointments and creams

-

Packaging of analgesic and anti-inflammatory gels

-

Dosage of dermatological preparations

Food industry

-

Filling tubes with flavour pastes and concentrates

-

Packaging of sauces and culinary additives

-

Dosing of high-viscosity products

Household chemicals industry

-

Production of cleaning pastes

-

Packaging of adhesives, silicones and other technical products

-

Dosage of toothpaste

Why choose Tarpak tubing machines?

When you choose tube machine solutions from Polish packaging machine manufacturer Tarpak, you gain:

-

Local service and technical support - rapid response and support throughout the country

-

Industry experience - long-standing presence on the market and specialisation in packaging machines

-

Competitive prices - value for money

-

Customisable solutions - adaptation of machines to specific customer needs

-

A qualified team - professional advice and service at every stage of cooperation

-

Innovative solutions - state-of-the-art technology to ensure reliability and precision

Tarpak is a company with tradition, operating in the market since 2005, which has established itself as a distinguished manufacturer of packaging machines. By choosing tubular machines from this brand, you not only get a high-quality machine, but also comprehensive support at every stage of cooperation.

The company provides a full service - from the delivery of the machine, to the installation and training of personnel, to the provision of an efficient service. With a skilled and experienced team, Tarpak also offers customisation of machine configurations to suit each customer's individual needs.

Tarpak tubing machines stand out in the market for their reliability and precise operation, which translates into a long service life of the machines and high quality of packaged products. The company relies on innovative solutions so that its machines are always in line with the latest trends in packaging process automation.